Why Choose Cestoil Nano MgO Additives?

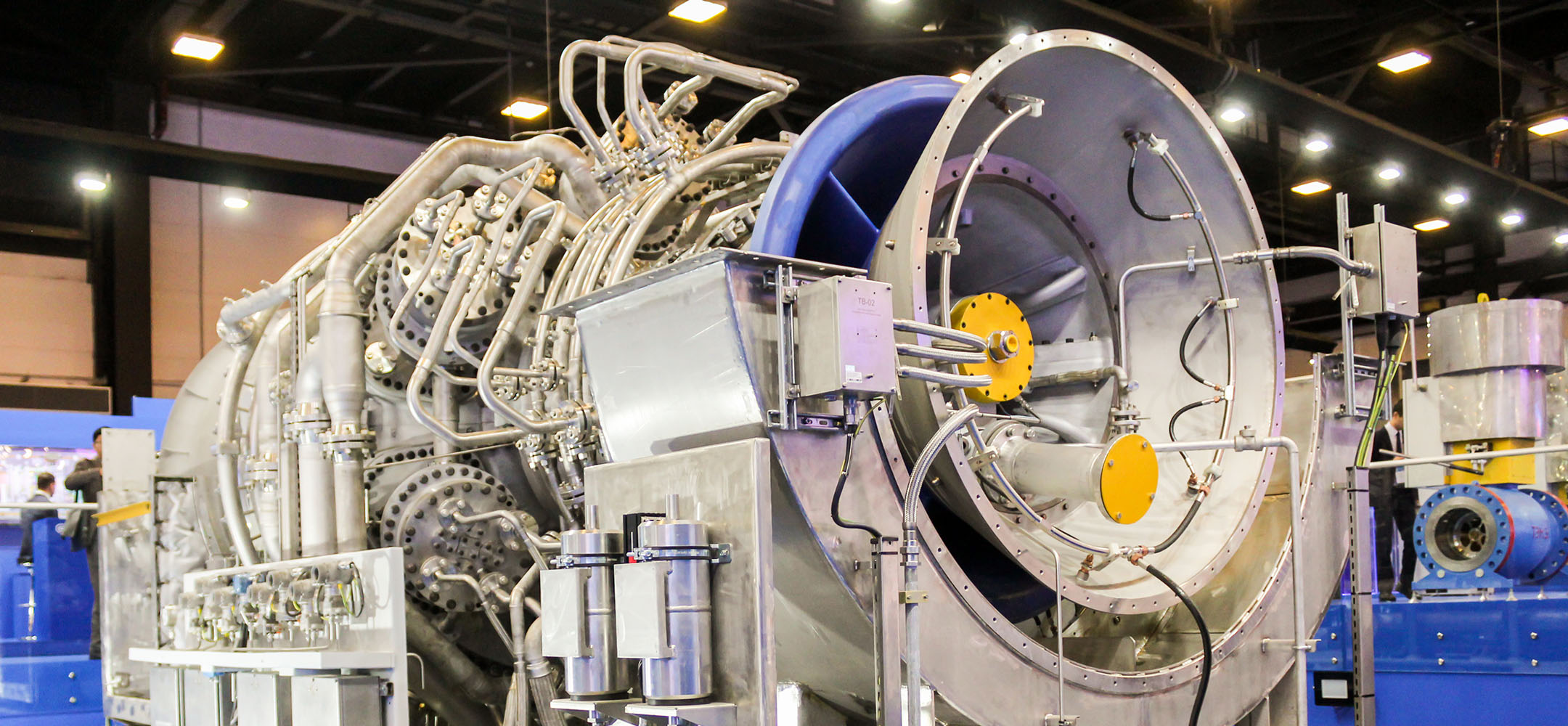

For many years, nano size MgO has been widely used to combat high-temperature corrosion caused by vanadium found in crude and fuel oils. Not only does it protect your gas turbines from vanadium corrosion, but it also reduces SO3 levels in flue gas and increases the acid dew point to prevent cold-end corrosion from H2SO4 and pressure drop across the air pre-heaters. Cestoil, a leading specialty chemical company, has developed an innovative product called Nano MgO additives, specifically designed to address these challenges in gas turbines.

GEK28150 Class A Approved

Cestoil’s Nano MgO additives have been rigorously tested and approved by GE, one of the leading manufacturers of gas turbines in the world. Our product meets the requirements listed as part of class A of the GEK28150 specification, ensuring that you can trust our additives to deliver outstanding performance and protection for your gas turbines.

Pure Nano Form & High Water Tolerance

Our Nano MgO additives are made using pure nano-sized magnesium oxide particles, which provide enhanced protection against vanadium corrosion. The high water tolerance of our additives ensures that they can be effectively applied in various operating conditions, maintaining their efficacy and performance even in high humidity environments.

Environmentally Friendly Solvents

At Cestoil, we are committed to protecting our planet. That’s why we use only pure, environmentally friendly solvents in our Nano MgO additives. By choosing Cestoil’s products, you can protect your gas turbines from vanadium corrosion while also reducing your environmental impact.

Protect Your Investment with Cestoil Nano MgO Additives

Don’t let vanadium corrosion damage your gas turbines and increase your maintenance costs. Invest in Cestoil’s Nano MgO additives and ensure the longevity and efficiency of your gas turbines while minimizing your environmental footprint. Contact us today to learn more about our innovative product and how it can benefit your operations.